Wear blocks are cushion blocks used in industrial and mining equipment.

Raw Material :

42CrMoNet weight :

0.4KGForging facility :

630T Friction pressMethod :

Hot forgingCycle time :

16Slead time :

30DAYSshipping :

FOB SHANGHAIcountry :

GlobalHot forging Carbon Steel Metal Forging Process

Hot forging Carbon Steel Metal Forging achieves strength and durability in the production of various industrial components..

| Raw Material | 40Cr |

| Net weight | 0.4KG |

| Forging facility | 630T Friction press |

| Method | HOT DIE FORGING |

| Cycle time | 16S |

| lead time | 30DAYS |

| shipping | FOB SHANGHAI |

| country | Global |

Nanjing Liju Precision Forging Co., Ltd. was established in 1998. It has been engaged in the development and manufacturing of automotive, forklift parts, electric power, aviation, industrial and mining, petrochemical metal and non-ferrous metal structural parts for many years. The process includes forging, casting, stamping, die-casting and other metal forming.

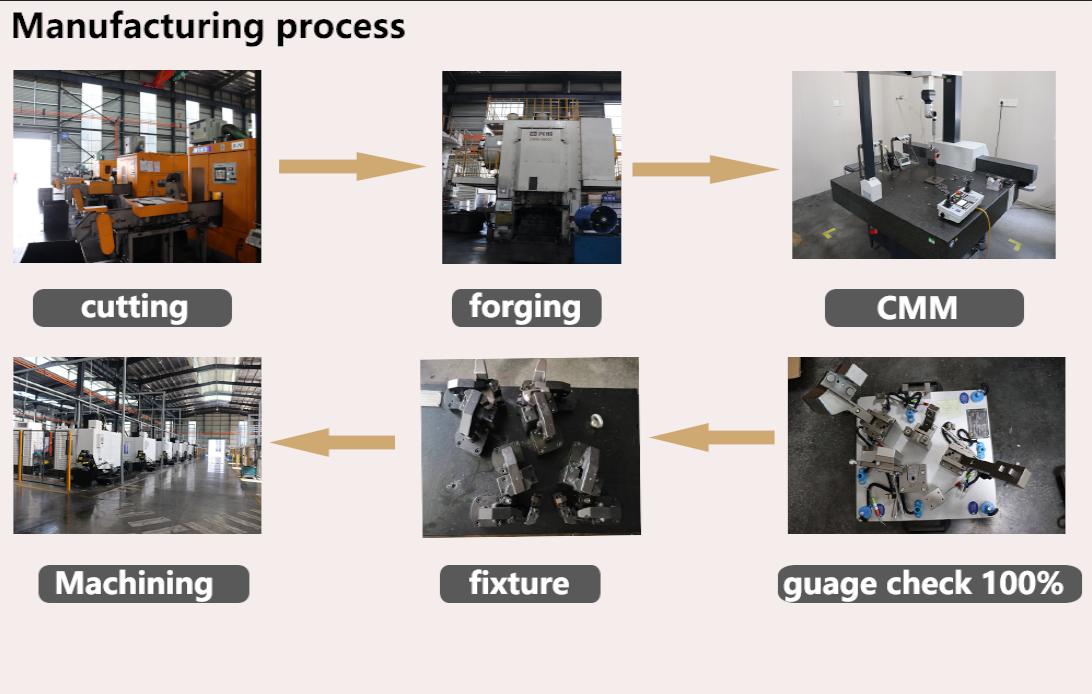

Forging process

Liju's Forged Components Division specializes in precision machine forging processes.

Forging is a manufacturing process in which metal is hammered, pressed, or rolled under high local pressure and shaped into high-strength parts called forgings. This metalworking method has been used for centuries and has been traditionally used to make tools, weapons, kitchen utensils and jewelry.

During the machining forging process, the coarse grain structure of the metal is broken down into finer grains, and a grain structure better aligned with the required directional strength can be obtained; in addition, pores may be removed during this process and low-density/empty spaces, and seal cracks.

As a result, forged parts are much stronger than parts produced by any other metalworking process. Therefore, forgings are widely used in applications where high strength is required, reliability and personal safety are crucial.

Liju's OEM customers span multiple large industries: automotive, off-highway, agriculture, marine, power transmission and other industries.

Advantages of hot forged parts include: excellent ductility, excellent quality/surface finish, flexibility to customize parts, and the ability to use aluminum or steel material grades. In order to meet the growing demand, we will continue to increase our production capabilities and invest in the latest advanced equipment to ensure that we continue to provide only high-quality precision machined hot forgings.

Main domestic and foreign customers: German KNORR, German EDSCHA, German TBVC, German WITTE, German AL KO, American EMERSON, Canadian PANGEO, Canadian FNG, Canadian NORTRAK, Changchun FAW Group Corporation, SAIC Donghua Transmission Shaft Company, Nanjing Quanfeng Automobile Parts companies, etc.

Q:Are you manufactuer?

A:Yes,we have factory and trading department.

Q:What is your delivery time?

A:Always it is 40-65 working days,but actually depends on the items you ordered.

Q:Have you test all the products before shipping?

A:Yes, all the goods will be tested before shipping. (check by guage 100%) And we have quality guarantee.

We hope do long-term business with all of you.